Quality Assurance at Peruweld

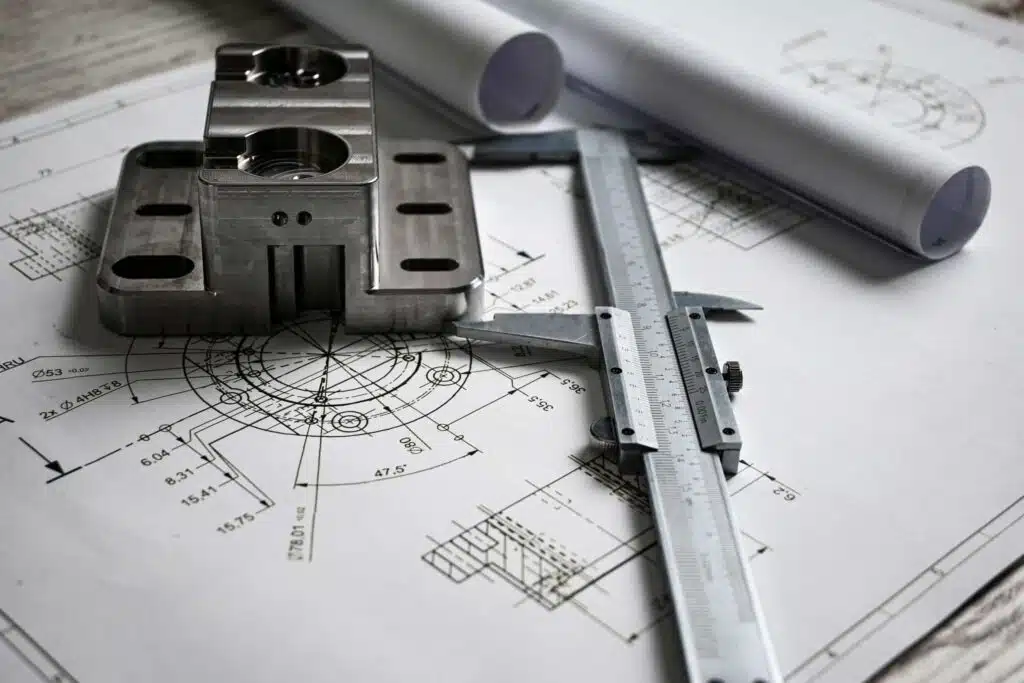

At Peruweld, quality assurance is a cornerstone of our operations. We believe that maintaining the highest standards of quality is essential for delivering products that meet and exceed our customers’ expectations.

Commitment to Excellence

Our quality system is built on the principles of continuous improvement and adherence to ISO 9001 standards. This ensures that our products are fabricated within deadlines, comply with construction codes, and meet customer specifications. Regular customer audits reinforce our dedication to maintaining the highest quality standards